Our company uses the latest technology to produce high quality seals tailored to the customer's needs.

We care about the environment, every process maximum of minimize environmental pollution.

Through the huge experience our professionals produce products which are a combination of high quality and very affordable prices.

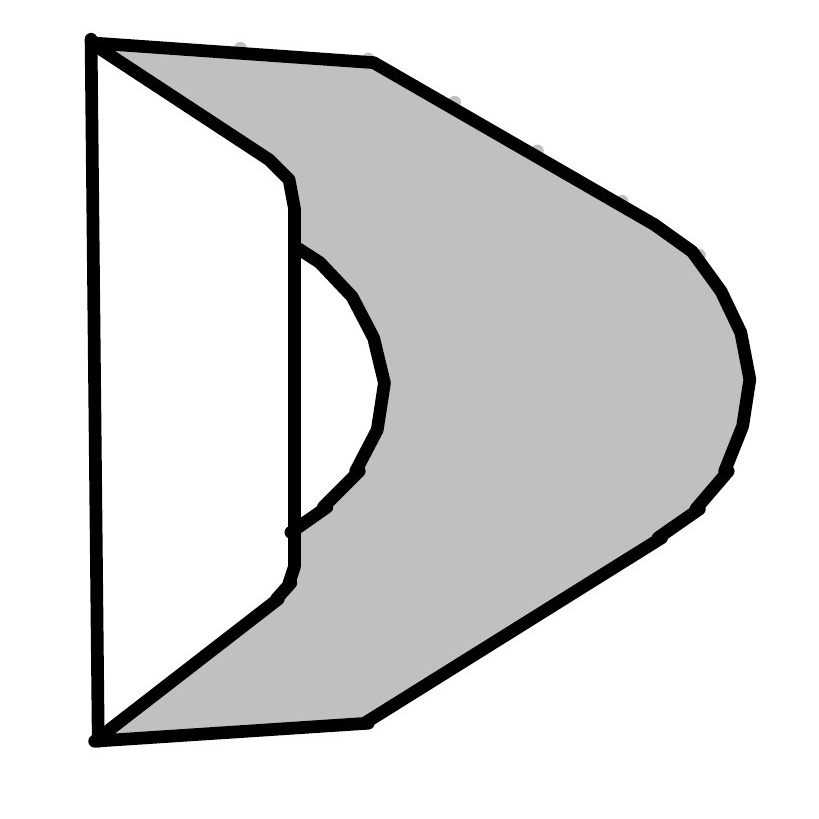

The shape of the V type seal is different from the other lip seals, but the working principle is similar. The mechanism of sealing is performed by clinching of lips on the surfaces of the cooperating parts. On the other hand, the V seal has a narrower lips and is devoid of the classical back part. Works with rings: supporting and clamping that support V seal. It should not work "solo" because of the low efficiency. With increasing the amount of seals in the package will increase the ability throttling. The package consists of 5 - 6 ring can be used for pressures about 40 MPa. Preferred is the use of the rubber V seal alternating with rubber-fabric type VT.

Detailed information available in the directory:

Download (PDF)

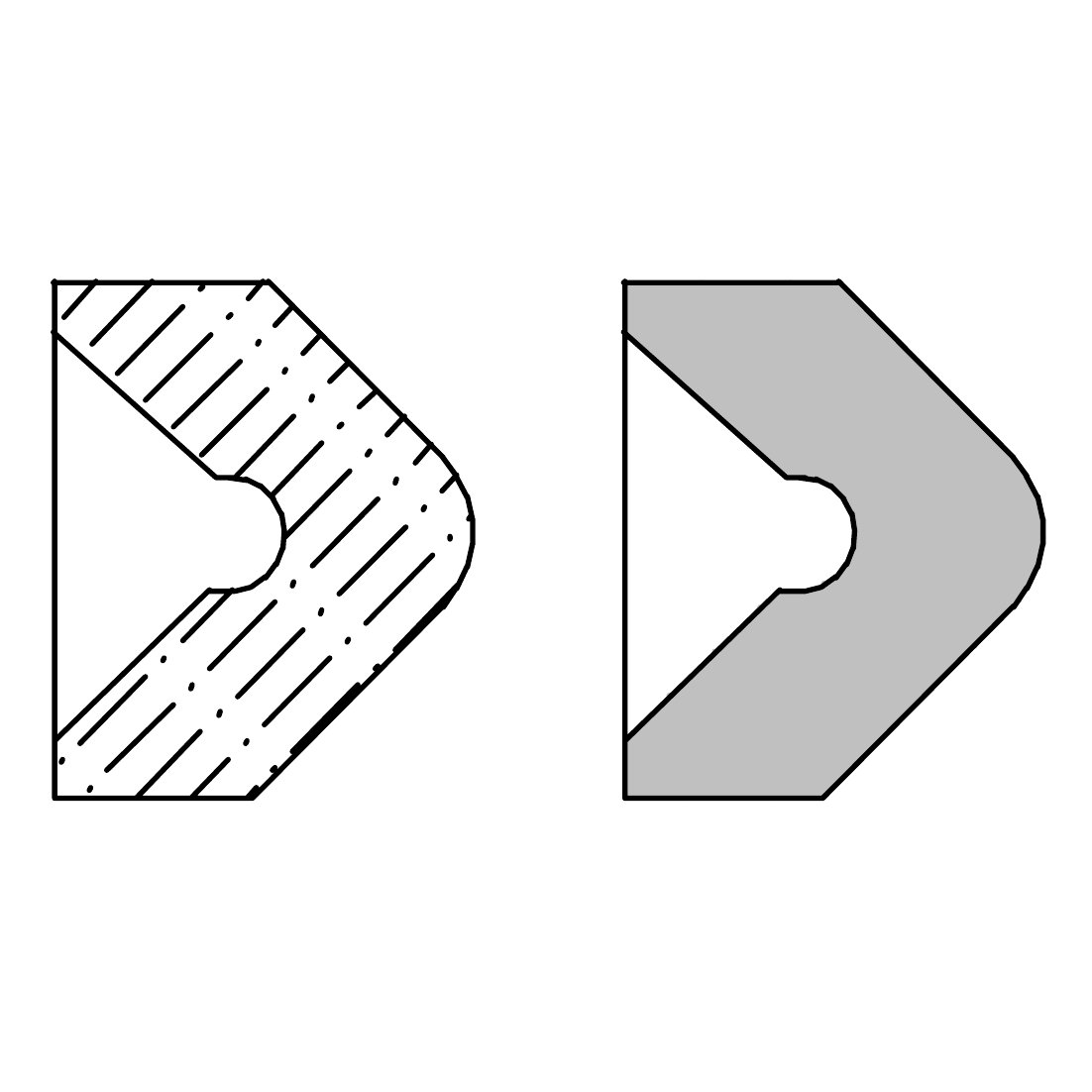

Seals with asymmetrical lips are a modification of the U2-type seals. An important drawback is the lack of universal use possibilities for sealing of reciprocating motion. On the other hand appreciated advantage is the prevent of lip collapse cooperating physically (lower lip) with a relative traverse of sealing element in a direction from the lip to the back of the seal.

Detailed information available in the directory:

Download (PDF)

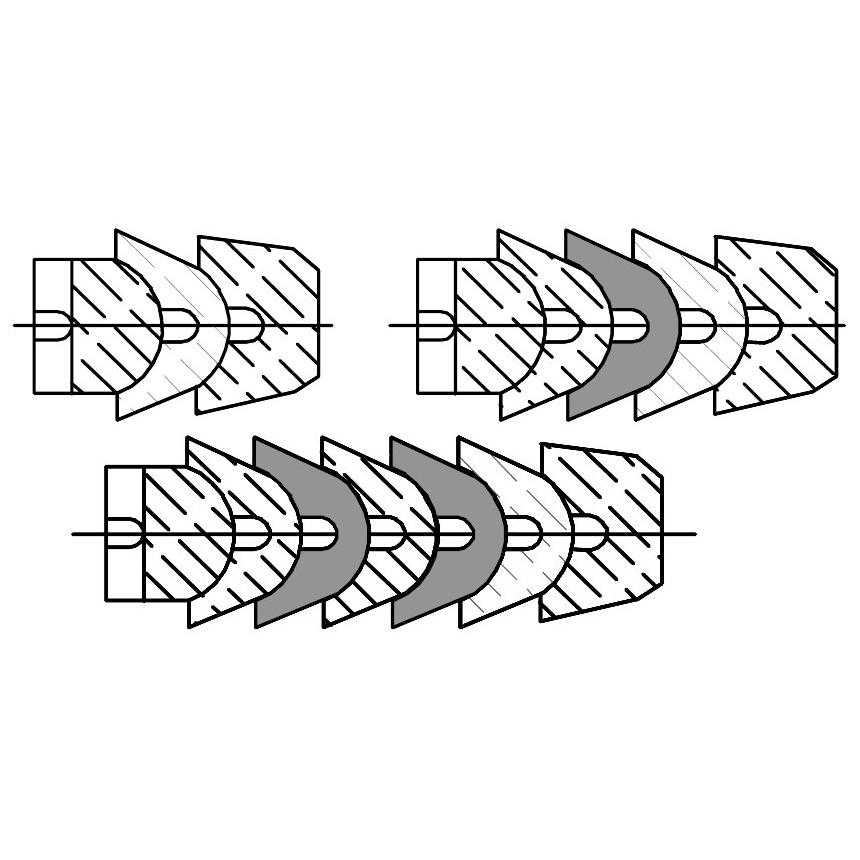

Fabric rubber has long been used material for sealing hydraulic cylinders and plungers operating under severe service conditions, particularly in hydraulic fluids, which is difficult to keep clean. Such conditions may include the work of sealing: agriculture, mining, metallurgy and mainly in those areas they are used.

Rubber-fabric material consists of a fabric, usually cotton, and blends of rubber combined with the fabric coating process or calendering. Packages of fabric rubber are in full sets as 3-DT1, DT2 and 5-seven-element-DT3. DT1 packages generally apply to seal the piston, while the packets DT2 and DT3 is recommended to seal the piston rod.

Detailed information available in the directory:

Download (PDF)

The design of the individual rings, analogous to the chevron rings from DT packages, has been adapted to work in sets for heavier working conditions and less accurate cabinetry, which is not recommended for normal DT packages. D1T ring is made of rubber while the cloth-rubber D1G. They are designed for bundling with the appropriate rings: supporting and clamping, performed in the framework of building elements. It is recommended to use D1T and D1G rings for sealing glands and plungers. Mounting rings should be held alternately, the rings D1T should be mounted at retaining rings. Allowed to use the same D1T rings.

Detailed information available in the directory:

Download (PDF)In order to improve service quality and increase production efficiency, we have implemented a quality management system ISO 9001:2008 and ISO 14001:2004.