Q-ring seals are complement of the technical o-ring offer . They are applicable to sealing knots with more complex structures nodes on a more complex sealing structures and wherein tightness is required in a large pressure range- low and high. When the materials with good technical characteristics are used to execute the q-ring, then we are obtained seal with more universally applicable than the O-rings.

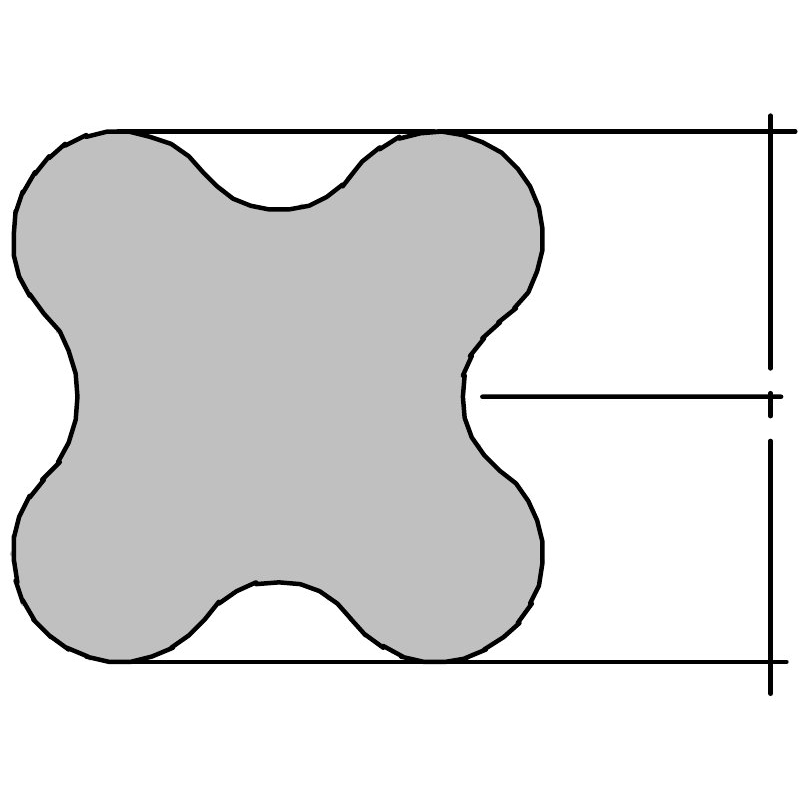

They can work: statically, in a reciprocating, oscillating and rotating (at low speed) as a double-acting seals. Q-ring is partially clamping with additional sealing pressure resulting from the shape , what is mainly due to the existence of elements of lip, causing more favorable, than in the o-rings, stress distribution of surface and line (peripheral). Completely symmetrical arrangement of lips arranged in a diagonal axis of the square causes that the seal is a double-acting. Stress distribution and the existence of continuous lubrication interlabial space allows the use of seals in the presence of dynamic load conditions (jumping, "peaks" and media pressure).

Application:

The biggest advantage of Q-rings is exceptional stability in reciprocating, oscillating and even torque. In these specific conditions, the O-rings twist in the building (groove), which accelerates their consumption, while the Q-rings only slightly move which does not affect their viability. It is recommended to use a Q-ring with the greatest possible cross-sections especially in dynamic applications because they can compensate for larger clearances. In the case of too large impression slots in the building and the presence of pulsating pressures should be used single releaser rings in the nodes of a single-acting and double in the nodes of a double-acting.Detailed information available in the directory:

Download (PDF)