Our company uses the latest technology to produce high quality seals tailored to the customer's needs.

We care about the environment, every process maximum of minimize environmental pollution.

Through the huge experience our professionals produce products which are a combination of high quality and very affordable prices.

In sealing technology meets the high range of the auxiliary rings designed to protect the work of essential seals, which determine the tightness of the system or assembly. Auxiliary rings operating in reciprocating include scraper rings, which are designed to prevent solid or liquid contamination in the form of dust, mud or active liquid with a moving rod or plunger or guide rod.

Particularly responsible role falls to the scraper rings operating in dusty conditions such as in mines, agriculture, construction machinery. In view of the above. function scraper rings are disposed between the environment contaminated with a basic seal or bushing or gland guide.

Detailed information available in the directory:

Download (PDF)

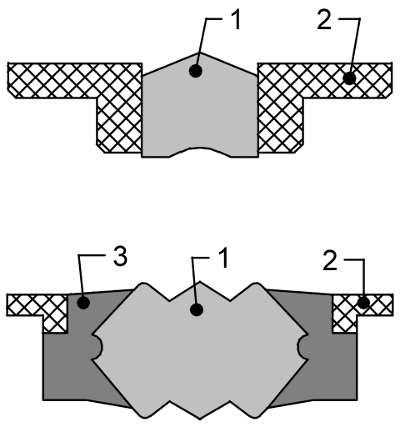

Compact type seal is a multi-structure, which, depending on: the burden on the sealing node, materials and the manufacturing technologies, has different designs. The most common types of seals include three-part and five-part compact.

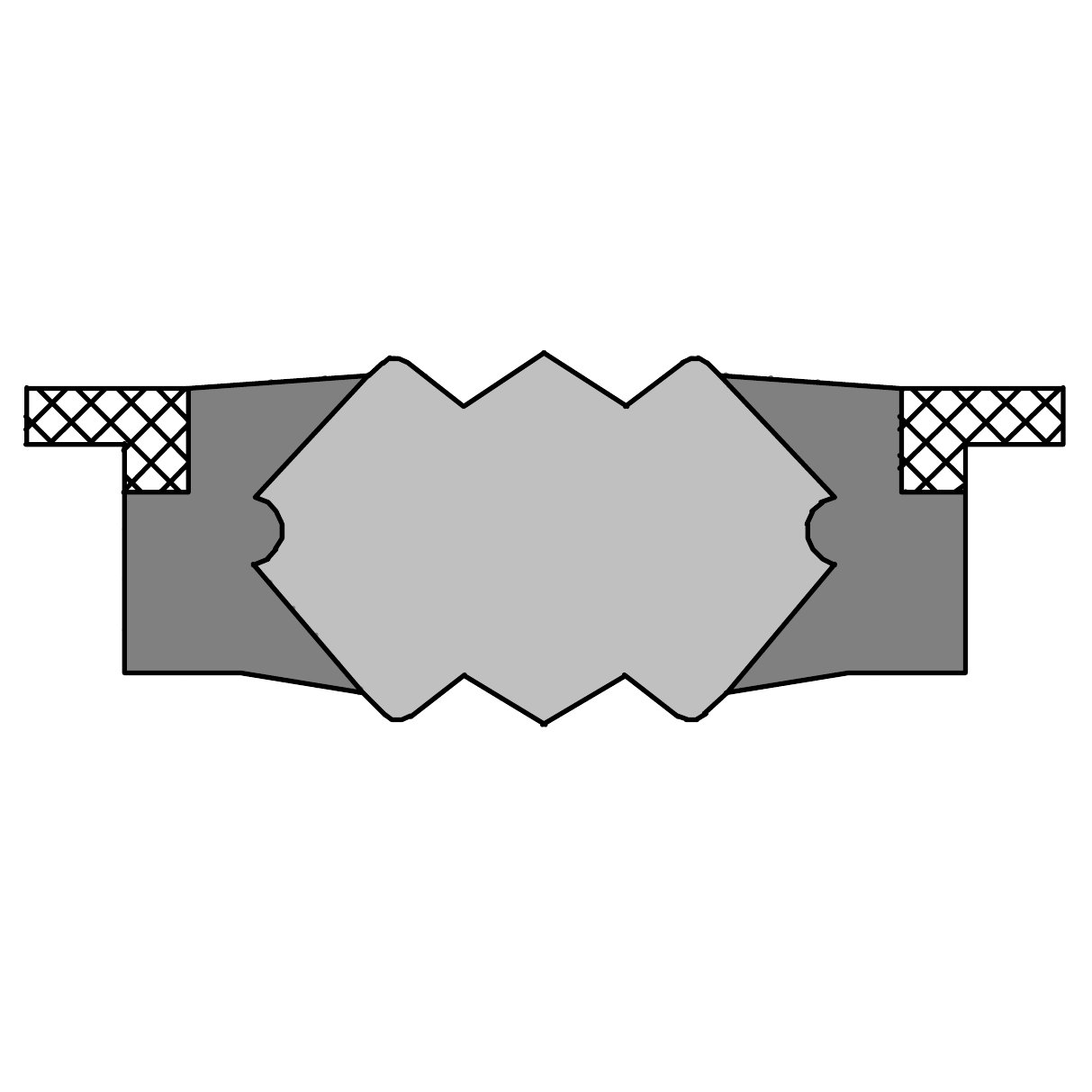

Sealing function of piston satisfies the o-ring pos. 1, which seals a result of a clamping section. The sealing rings are generally made of rubber with a hardness of 80-90 IRHD. Before pressing into the gap between piston and cylinder, the sealing ring protect support rings on both sides to pos. 3, which are made of a material with a higher modulus of elasticity and strength. In addition, support rings should have the ability to adapt its shape to the cross-sectional profile of the sealing ring under variable pressure and direction of thrust force on the piston. For proper cooperation in the conduct of the piston in the cylinder correspond Support-leading rings pos. 2, which carry the friction derived from the transverse forces and longitudinal pressure exerted by the sealing ring via the retaining ring and pressure from the sealed medium. Support-leading rings are made of thermoplastics with good sliding properties and high resistance to surface pressures. Pressure and resistively-guide rings are cut at the periphery in order to enable their assembly in the chamber of structure. Three-part assemblies do not have a separate supporting rings and partially fulfill the function of the guide rings, which limits their use in high pressure conditions.

Detailed information available in the directory:

Download (PDF)

Sealing rings made of PTFE composites usually consist of two elements:

The support ring serves as a prandial producing an initial peripherally-radial emphasis as a result its modulus of elasticity. Sealing ring transfers radial forces on mobile structure as a result of the impact of the support ring and the pressure of sealed medium. These seals are used to seal the pistons (OW1) and rod (OW3), hydraulic cylinders when it is desired to save space of node and working in high-speed.

Detailed information available in the directory:

Download (PDF)ZWWG also provides services in the field of production of non-standard. With technical drawing and knowing the customer's requirements, our specialized staff is able to produce from the raw material a very high quality product. Non-standard products is a sector of our business, which was special recognition mainly on foreign markets, such in Western Europe and Africa, which proves the quality of our services.

In order to improve service quality and increase production efficiency, we have implemented a quality management system ISO 9001:2008 and ISO 14001:2004.