Our company uses the latest technology to produce high quality seals tailored to the customer's needs.

We care about the environment, every process maximum of minimize environmental pollution.

Through the huge experience our professionals produce products which are a combination of high quality and very affordable prices.

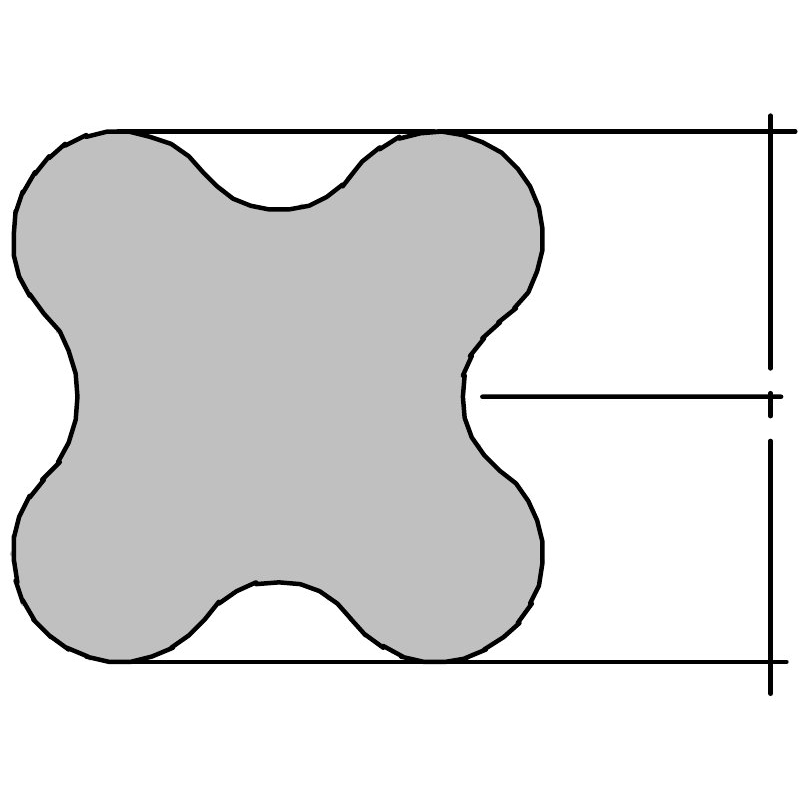

Q-ring seals are complement of the technical o-ring offer . They are applicable to sealing knots with more complex structures nodes on a more complex sealing structures and wherein tightness is required in a large pressure range- low and high. When the materials with good technical characteristics are used to execute the q-ring, then we are obtained seal with more universally applicable than the O-rings.

They can work: statically, in a reciprocating, oscillating and rotating (at low speed) as a double-acting seals. Q-ring is partially clamping with additional sealing pressure resulting from the shape , what is mainly due to the existence of elements of lip, causing more favorable, than in the o-rings, stress distribution of surface and line (peripheral). Completely symmetrical arrangement of lips arranged in a diagonal axis of the square causes that the seal is a double-acting. Stress distribution and the existence of continuous lubrication interlabial space allows the use of seals in the presence of dynamic load conditions (jumping, "peaks" and media pressure).

Detailed information available in the directory:

Download (PDF)

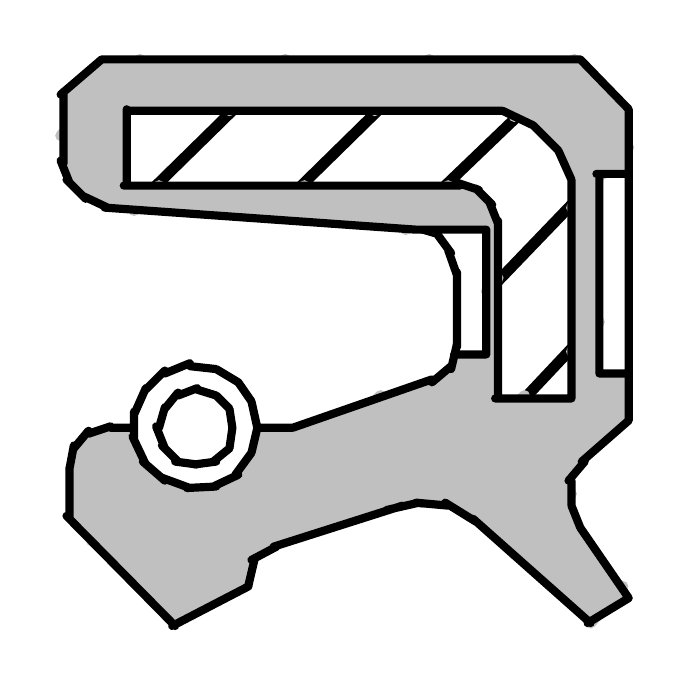

Simmering seals a rotating shafts (other determinations of simmerings: Simmer seals, radial shaft seals, rings seals a rotating shafts PUWO) are ones of the most common rotation seals.

They have:

Rings sealing rotating shafts have a wide variety of designs, due to a very wide application in many industries, and are made of materials which guarantee their use in a big range of technical parameters.

Detailed information available in the directory:

Download (PDF)

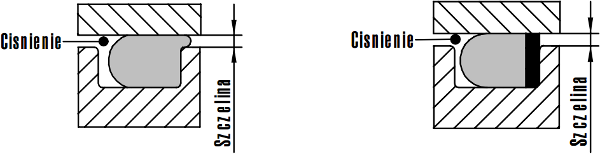

If the ring O-ring as a result of external factors is exposed to flow through the gap of the structure, should be added security called back-up ring. This takes place in the following cases:

The mechanism of insertion seal into the building gap and a method for the prevention is shown in the following drawings:

Detailed information available in the directory:

Download (PDF)

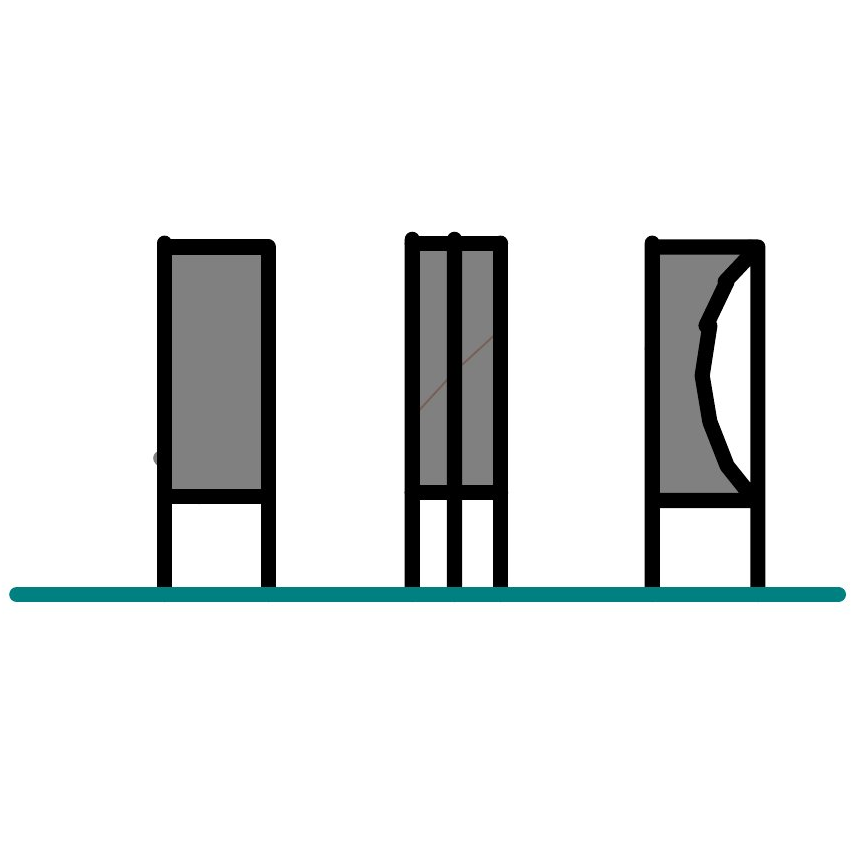

Cords are designed primarily for sealing static and movement knots, which work as a flexible seals. Construction principles of these seals are identical as the O-ring. Prior to installation should make a lasting connection to the required size by gluing or vulcanization. An example of how to combine is shown in the figure below.

Detailed information available in the directory:

Pobierz plik (PDF)In order to improve service quality and increase production efficiency, we have implemented a quality management system ISO 9001:2008 and ISO 14001:2004.