Our company uses the latest technology to produce high quality seals tailored to the customer's needs.

We care about the environment, every process maximum of minimize environmental pollution.

Through the huge experience our professionals produce products which are a combination of high quality and very affordable prices.

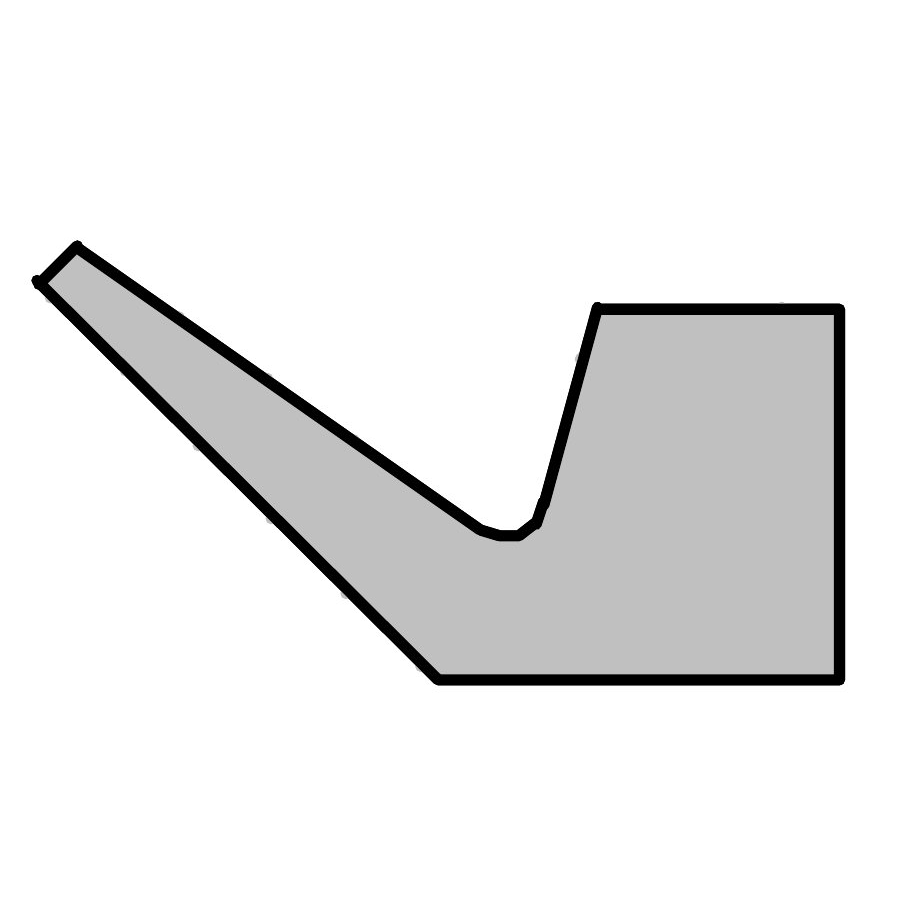

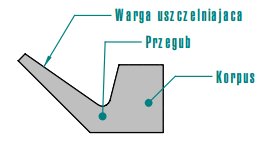

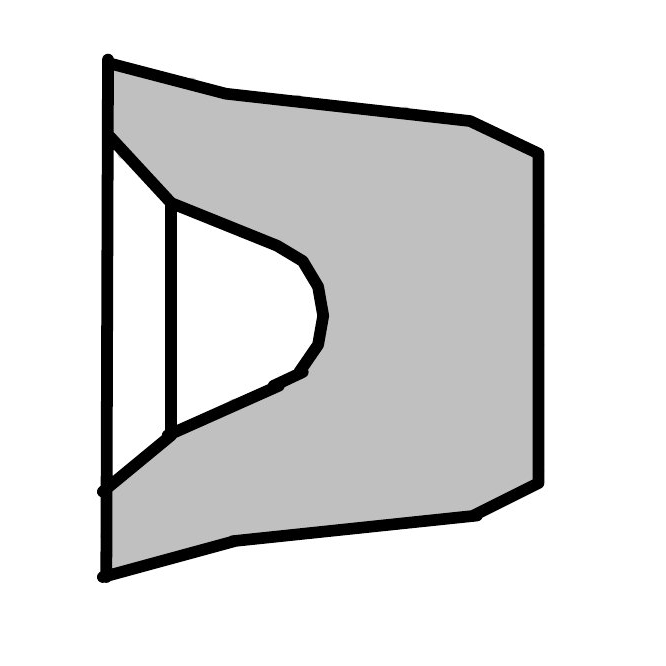

V-rings are included to seals of rotary shafts and in contrast to the simmerings, they seal in the axial direction on the front face of the bearing seat (fixed element) and rotate with the shaft. These rings have very simple construction and principle of operation. They are used for operation "solo", and cooperating with thr other type of seals operating in rotation. Demonstrate the ability to work on a "dry" and therefore can operate in dusty conditions. Among the advantages of these seals is the ability to apply them with greater eccentricity of the shaft and housing and the elimination of precise machining of the shaft.

V-ring consists of three elements:

Front flexible ring having a diameter slightly smaller than the diameter of the shaft is mounted on it with an appropriate clamp and rotates together with the shaft. The flexible sealing lip is adjacent to the sealable surface, achieved by the axial clamp seal assembly.

As shown in the figure below the sealing lip prevents the penetration of liquid from the outside and impurities.

Detailed information available in the directory:

Download (PDF)

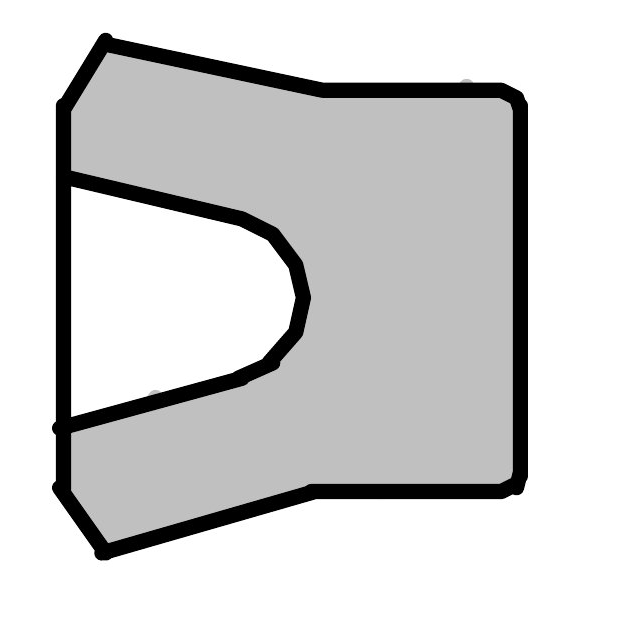

Seals type Multiseals apply for sealing joints and screw connections of hydraulic power units.

They consist of two parts:

Both parts are vulcanized together and they are inseparable connection.

Detailed information available in the directory:

Download (PDF)

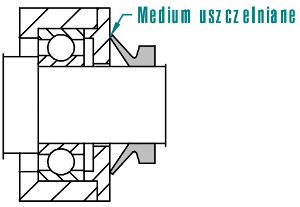

U1 design is based on PN-72/M-73095 and applies in hydraulic drives with working pressure up to 16 MPa with the possibility of working on the piston or piston rod of the hydraulic cylinder.

The ring is shaped so that when assembled in the structure it provides initial clamp and thus retains tightness without pressure. With increasing pressure of contact surface, which is gradually increased over whole height contact surface pressure is gradually increased over the whole height of the seal. The increase of pressure above the limit value for the material causes to flow it through the gap on the dorsal side.

Detailed information available in the directory:

Download (PDF)

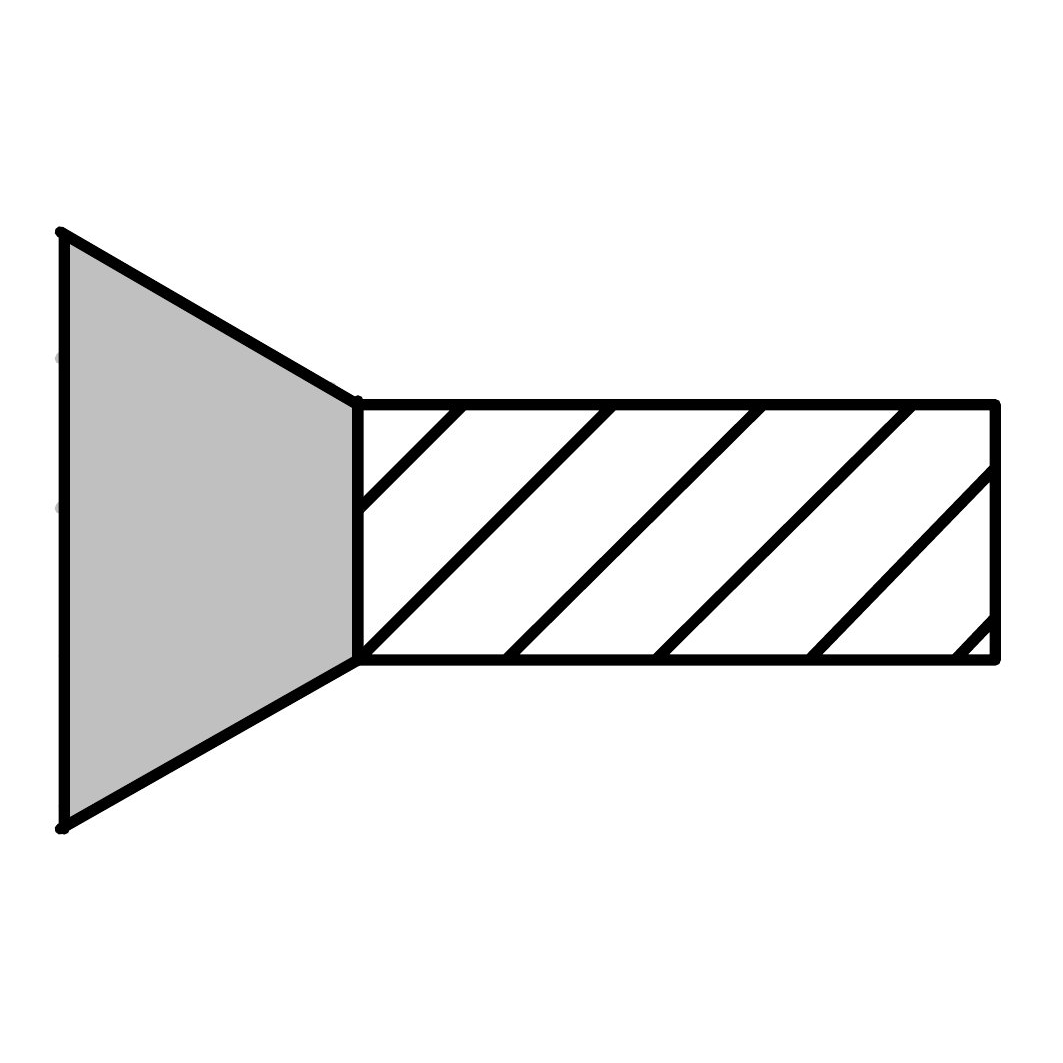

U2 are used to seal the knots of reciprocating motion higher dynamic working conditions than rings U1. They do not require supporting rings. The geometry of the U2 seal is based on short and thick lips provide high of size contact pressures or the high value of the pressure in the throttle slot. Pressure of ring lips to the sealing surface increases with the increase of self-pressure medium. There is no risk of damaging the surface due to galling, because the configuration of the grove ring lips allows lubrication of gap, even at high pressure which allows the use of U2 in wide range of pressures.

Detailed information available in the directory:

Download (PDF)In order to improve service quality and increase production efficiency, we have implemented a quality management system ISO 9001:2008 and ISO 14001:2004.