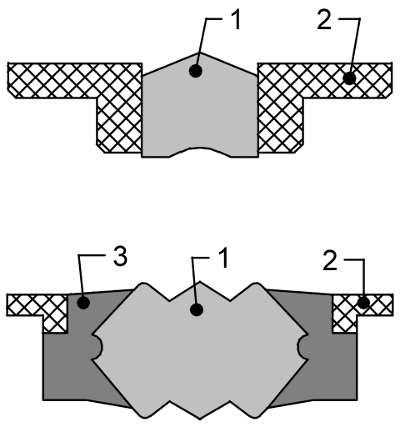

Compact type seal is a multi-structure, which, depending on: the burden on the sealing node, materials and the manufacturing technologies, has different designs. The most common types of seals include three-part and five-part compact.

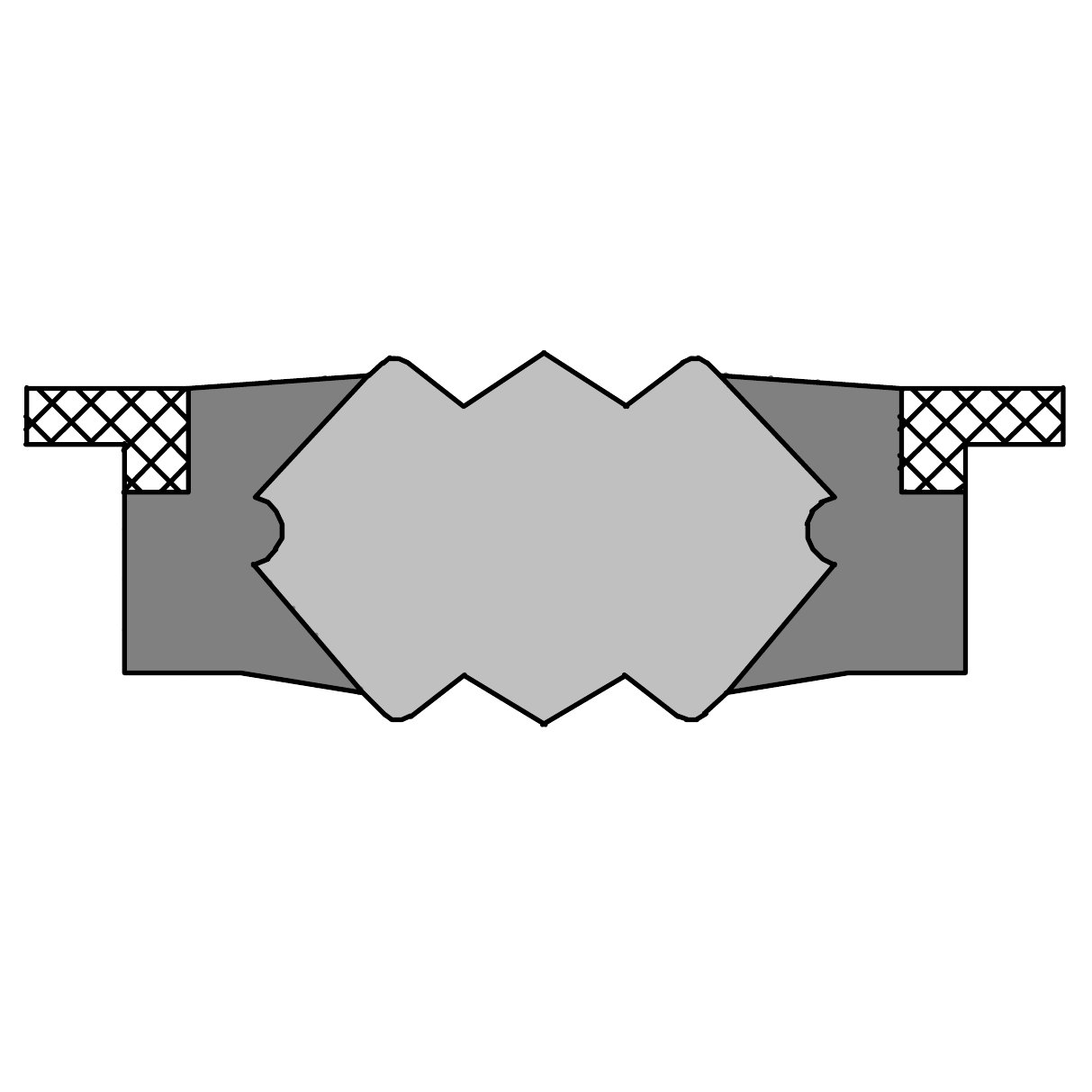

Sealing function of piston satisfies the o-ring pos. 1, which seals a result of a clamping section. The sealing rings are generally made of rubber with a hardness of 80-90 IRHD. Before pressing into the gap between piston and cylinder, the sealing ring protect support rings on both sides to pos. 3, which are made of a material with a higher modulus of elasticity and strength. In addition, support rings should have the ability to adapt its shape to the cross-sectional profile of the sealing ring under variable pressure and direction of thrust force on the piston. For proper cooperation in the conduct of the piston in the cylinder correspond Support-leading rings pos. 2, which carry the friction derived from the transverse forces and longitudinal pressure exerted by the sealing ring via the retaining ring and pressure from the sealed medium. Support-leading rings are made of thermoplastics with good sliding properties and high resistance to surface pressures. Pressure and resistively-guide rings are cut at the periphery in order to enable their assembly in the chamber of structure. Three-part assemblies do not have a separate supporting rings and partially fulfill the function of the guide rings, which limits their use in high pressure conditions.

Detailed information available in the directory:

Download (PDF)